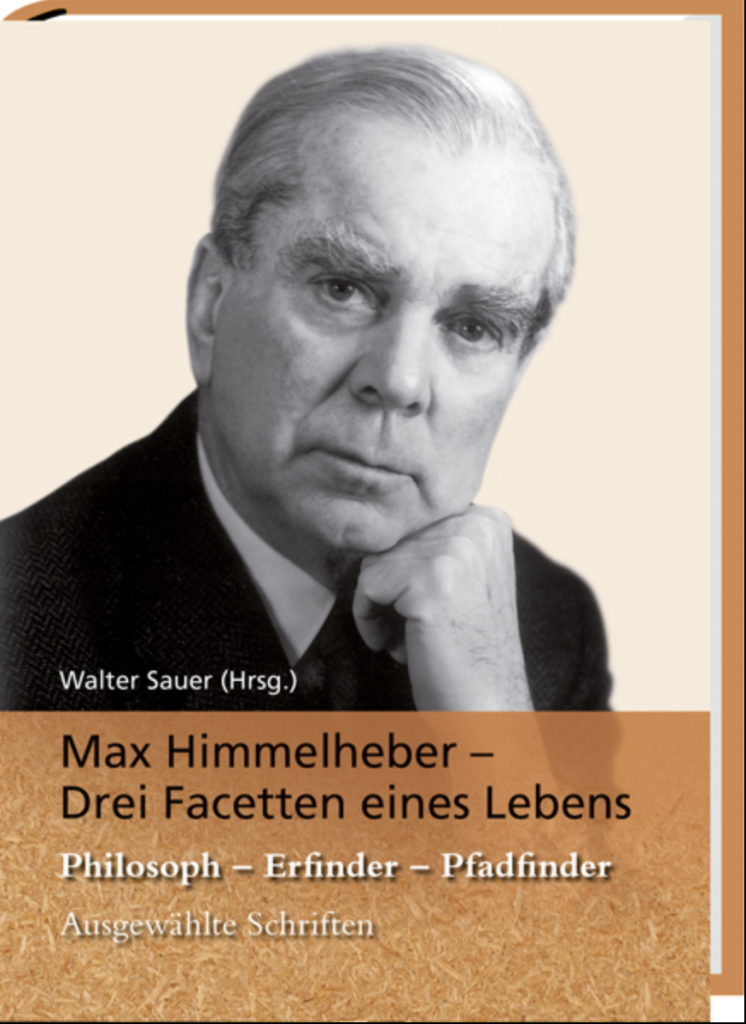

A light is shone on engineer/entrepreneur Himmelheber, and his rather ill-fated contribution toward the fledgling environmental movement- namely chipboard.

An ingenious material originally using waste material from sawmills – bound with phenol resin, these chips and sawdust were constituted from the approximate 40% waste from the production of planks, a highly inefficient processing. Himmelheber approached the use of these materials in the spirit of frugality and economy, which resulted in a highly versatile, supposedly stable product. Chipboard now accounts for 80% of the material in furniture produced globally, and has spawned a love-hate relationship due its disposability, and more recently discovered environmental impact .

The Sceptical Structures of Max - Installation View

With the management of patents, Himmelheber amassed a fortune, turned recluse and shifted his attention to a set of philosophical reflections on mans role in the industrialised world. In his quarterly magazine, Scheidewege (Crossroads), he published texts displaying a culturally conservative distrust of unreflected technical and scientific progress. The journal was thus subtitled “Für skeptisches Denken” – For Sceptical Thinking. Losing a bit the plot, his contributions were at times dreamy and unintentionally comical, such as “On the Beauty of Whales and Dolphins”. Later texts denounce capitalism in favour or socialist workshops, whereby unemployed youth would create their own furniture from “solid wood”, a kind of heresy of his own product.

The Sceptical Structures of Max - Installation View

The proliferation of Himmelheber factories around the world meant Max would spend much time in Japan, exposure which sparked a long term interest in Shinto animism. Back in his home town, he commissioned the architect of his first factory to build an oriental inspired villa, a modernist hybrid translating his fantasies to home. The refined aesthetics and visible decay of this structure form the backbone of the installation – rendered in chipboard harvested from the streets of Amsterdam. The humbled bodies of former kitchens, wardrobes, tv stands and beds reflect a state of both discard and exhaustion. At the seeming end of an era, this installation proposes a form of redemption through a consideration, re-ordering and caring of materials.

The Sceptical Structures of Max (05 - Coffee and Shrine) - Installation detail

BAMBOO CUP HEALTH RISK

07 August 2019

Website: I AM EXPAT

cups are officially in vogue: an especially lauded alternative to disposable coffee cups. You might think you’re doing your bit for the environment by using a bamboo cup – but new research by the German consumer group Stiftung Warentest has shown that you might be risking your health in the process. This reputable consumer organisation that investigates and compares goods on the German market has warned people to “keep [their] hands off bamboo cups” and opt for other reusable drinks containers instead.

With descriptions such as “bamboo mug” or “made from bamboo fibres”, producers gloss over the fact that the cups are made from a powder of finely-ground bamboo fibres that are then glued together.

All of the cups tested contained melamine resin, a kind of plasticky glue made from formaldehyde and melamine. Melamine is suspected of causing damage to the bladder and kidneys, while formaldehyde is an familiar irritant and known carcinogen.

Ecoffee cup (bamboo composite reusable coffee cup), Kerr and Napier – 250ml with silicon heat resistant brace

The Sceptical Structures of Max (05 - Coffee and Shrine) - Installation detail

The Sceptical Structures of Max (02+03 - Tubular, Shrine + Bamboo) - Installation view

The Sceptical Structures of Max (03 - Bamboo) - Installation detail

The Sceptical Structures of Max (02 - Tubular and Shrine) - Installation detail

SAUERLAND SPANPLATTE

1951 – today

Website: sauerland-spanplatte

board manufacturer Sauerland Spanplatte is located in the eponymous wooded region of Arnsberg, Germany. Established in September 1951, the family-owned board manufacturer produces chipboard with an extrusion-method developed and patented in 1949.

Wood chip pulp is poured around metal tubes with varying diameters and compacted to form boards that are then cut to desired sizes. The stress distribution principal in the tubular material takes its inspiration from the architecture of dome-shaped dwellings such as igloos, or arched aqueducts – elevated structures that mainly support mass that cross bodies of water. The arch leads to an ideal absorption of force, allowing the bridge to let the water flow through; in the case of tubular boards it allows the boards to be thick while being light in weight and impact resistant.

The main application of the boards is for doors; Sauerland Spanplatte specializes in the production of doors that are fire, sound and climate resistant.

Natural residual wood and chips from the saw mills in Sauerland and Thuringia form the basis for the Sauerland particle board. More than 1 million cubic metres of softwood are processed annually ensuring optimum and environmentally friendly raw material utilisation. The company employs approximately 300 workers.

The Sceptical Structures of Max - Installation View

The Sceptical Structures of Max (01 - Bois Durci, Shrine and Scheidewege) - Installation view

The Sceptical Structures of Max (01 - Bois Durci, Shrine and Scheidewege) - Installation detail

The Sceptical Structures of Max (01 - Bois Durci, Shrine and Scheidewege) - Installation detail

MAX HIMMELHEBER

Scheidewege Journal – 1975

Symptom Therapy and Cure using the Example of the Waste Water Problem

“In the summer of 1953 I initiated operation of a factory in Hokkaido which had been built in German-Japanese cooperation. On the day when the first trial run was to begin, a Shinto priest came to our boiler house early in the morning, where the Japanese staff had gathered with the boss. Together with his altar boys, he attached red prayer strips to manometers, water level glasses and valves of the steam boilers. Then followed a short rite, which I interpreted as a consecration or blessing.

“We apologize to the spirit of the water for seizing the spring and for forcing it to drive our steam turbines,” a young Japanese engineering colleague told me.”

Dense particle fibreboard found in private Shinto shrine at the back of Villa Himmelheber, Baiersbronn, DE

The Sceptical Structures of Max (01 - Bois Durci, Shrine and Scheidewege) - Installation detail

The Sceptical Structures of Max (01 - Bois Durci, Shrine and Scheidewege) - Installation detail

BOIS DURCI

1855 – now

The Plastics Historical Society

Durci (French: hardened wood) could perhaps be described as the best Victorian achievement of a ‘plastic’ based on an animal polymer. The technique was patented in France in 1856 by Francois Charles Lepage, which he then declared ‘A New Composition of materials which may be employed as a substitute for wood, leather, bone, metal and other hard or plastic substances’.

His composition was made up from blood (from the Paris slaughterhouses) and powdered wood, mixed with colouring to simulate wood. A recipe typically used 4 parts of ebony or rose wood “flour” and 1 part of ox blood albumin. The paste was then dried in a stove maintained at a constant temperature, then ground to a fine powder. In this state it was then pressed in heated steel moulds by a powerful hydraulic press, resulting in a dense and glossy finish.

The combination of wood and the organic molecules of blood albumin increase the wood’s resistance to mechanical agents considerably, and the procedure’s leniency towards detail make it a perfect material for statuettes, medallions, and various objets d’art.

The SOCIETE DU BOIS DURCI was established to produce desk items, especially decorative inkwell stands and plaques. They continued to make Bois Durci until about 1920, by which time it had been superseded by newer plastic materials, such as bakelite.

The Sceptical Structures of Max (01 - Bois Durci, Shrine and Scheidewege) - Installation detail

SCHEIDEWEGE

1971 – 2000

‘Journal For Sceptical Thinking’

roads first appeared in 1971 as a reflective journal published by the Max Himmelheber Foundation. Till 2000 it dealt with controversial ecological, philosophical, cultural and historical issues. As one of the first periodicals to work on the concept of environmental sustainability, it displayed a culturally conservative distrust of unexamined technical and scientific progress, and was thus subtitled “für skeptisches Denken” – a journal for sceptical thinking.

Scheidewege served as a platform for Himmelheber and his at times dreamy and unashamedly romantic contributions, such as “On the Beauty of Whales and Dolphins”. At times more ominous than hopeful, the Scheidewege manifesto claimed examination can and must begin everywhere: “Yesterday cannot be repeated, but tomorrow cannot simply be an improved form of today. Retreating into tradition is as hopeless as the notion that progress has an appropriate mechanism of self-regulation that will finally turn everything in the right direction”.

As a reflection from Himmelheber (and amongst its contributors, a larger community of engineers) Scheidewege is much overlooked as an untapped potential toward the Green movement.

The Sceptical Structures of Max (Table with original plates from Himmelheber archive cir. 1945- 1957) - Installation detail

The Sceptical Structures of Max (Table with original plates from Himmelheber archive cir. 1945- 1957) - Installation detail

The Sceptical Structures of Max (Table with original plates from Himmelheber archive cir. 1945- 1957) - Installation detail